In the Cronin group, we currently have (among others) two Ultimaker 2 and two Ultimaker 2+. They are good quality Fuse Deposition Modeling (FDM) printers, but because they have only one extruder, they can only print one material at a time.

When printing complicated models with overhangs (parts of the model that rest on nothing), it is common to also print some supports. These supports are here to provide a surface on which overhangs can be printed on. They are supposed to be easy to remove once the printing process is finished, but let’s not lie: a) it is not always easy to remove them b) the final aspect does not look great. It requires manual post-processing of the printed model to make it look nice, or to make it functional if it is a part of a mechanical assembly. That is a point where FDM printers fall short compared to “industrial” 3D printers that can print soluble supports.

Recently, Ultimaker released its last FDM printer: the Ultimaker 3. While the difference between an Ultimaker 2 and an Ultimaker 2+ was slim, the Ultimaker 3 has tons of new features and is really different to any FDM printer made before. I will not describe all these new features here, but I will say it has two extruders (which means it can print two materials at a time). And Ultimaker sells a soluble material, a polymer called PolyVinyl Alcohol (PVA).

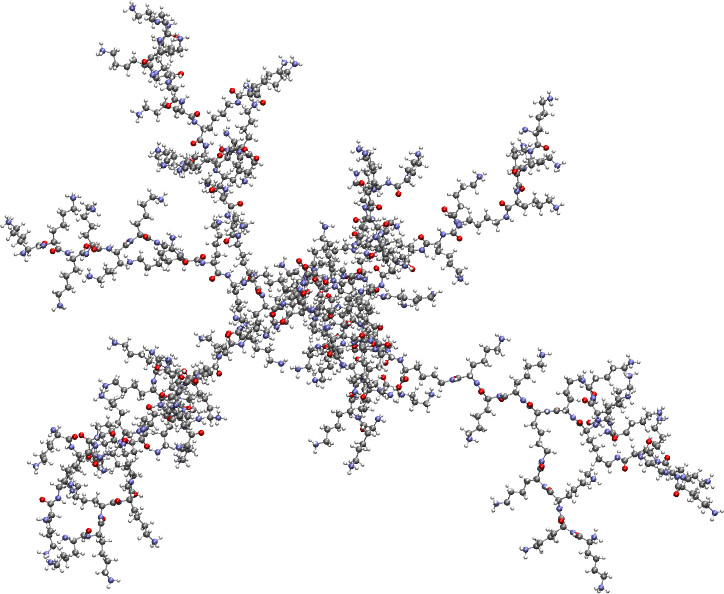

I wanted to test the dual extruder, and I decided to print a model I knew was just impossible to print: a DGL G3 (for more information about DGLs, see this publication). Here is what it looks like in a CPK representation:

You can download the PDB here. I used VMD to render a “Surf” representation of this molecule to a STL file (format used by 3D printing softwares to prepare the printing process).

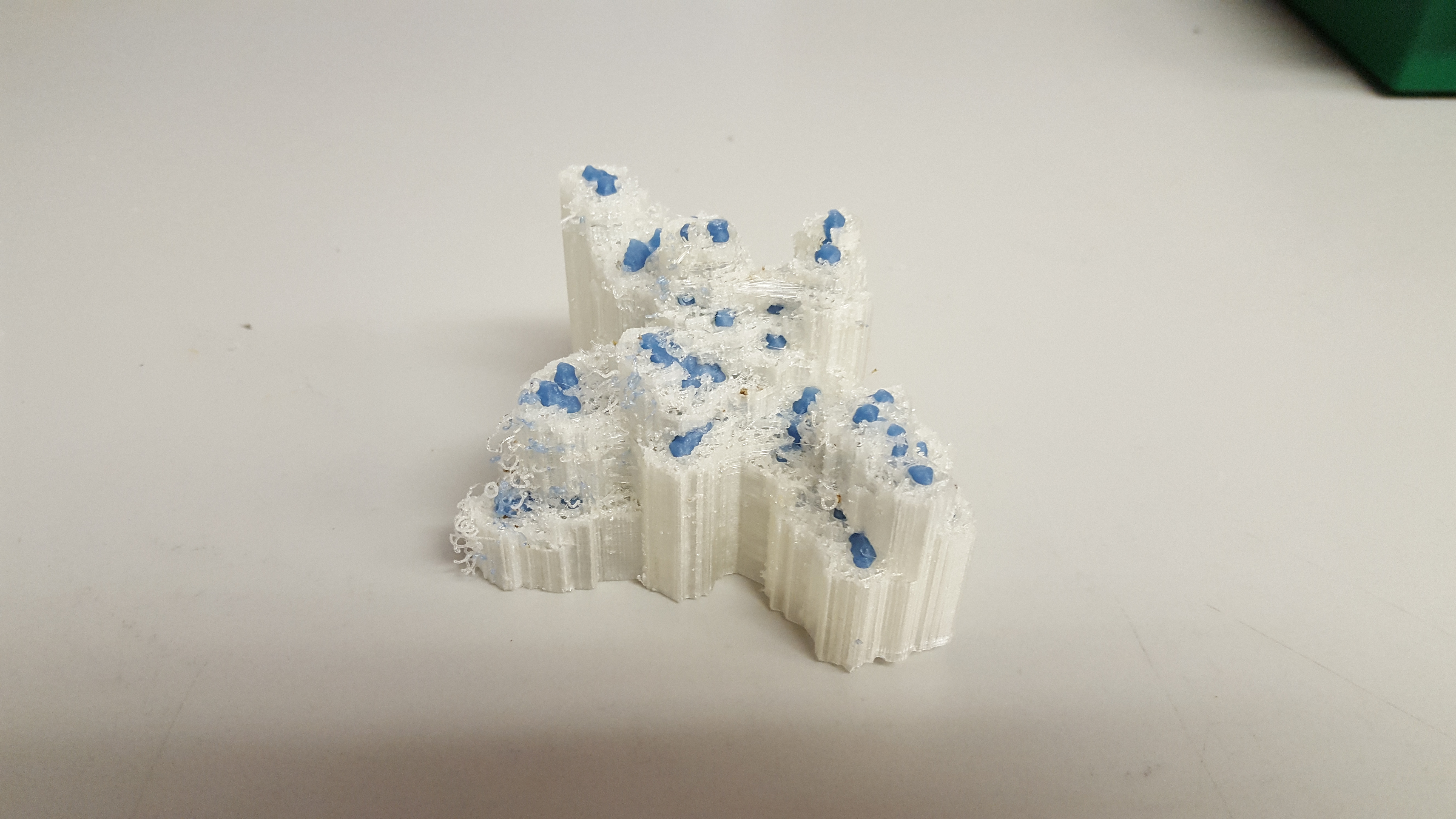

Then I printed this model with this PolyLactic Acid (PLA) in the first extruder, and Ultimaker PVA in the second one. The second extruder was used to print the supports. I printed this model with layers of 100 µm, and here is what it looks like once printed:

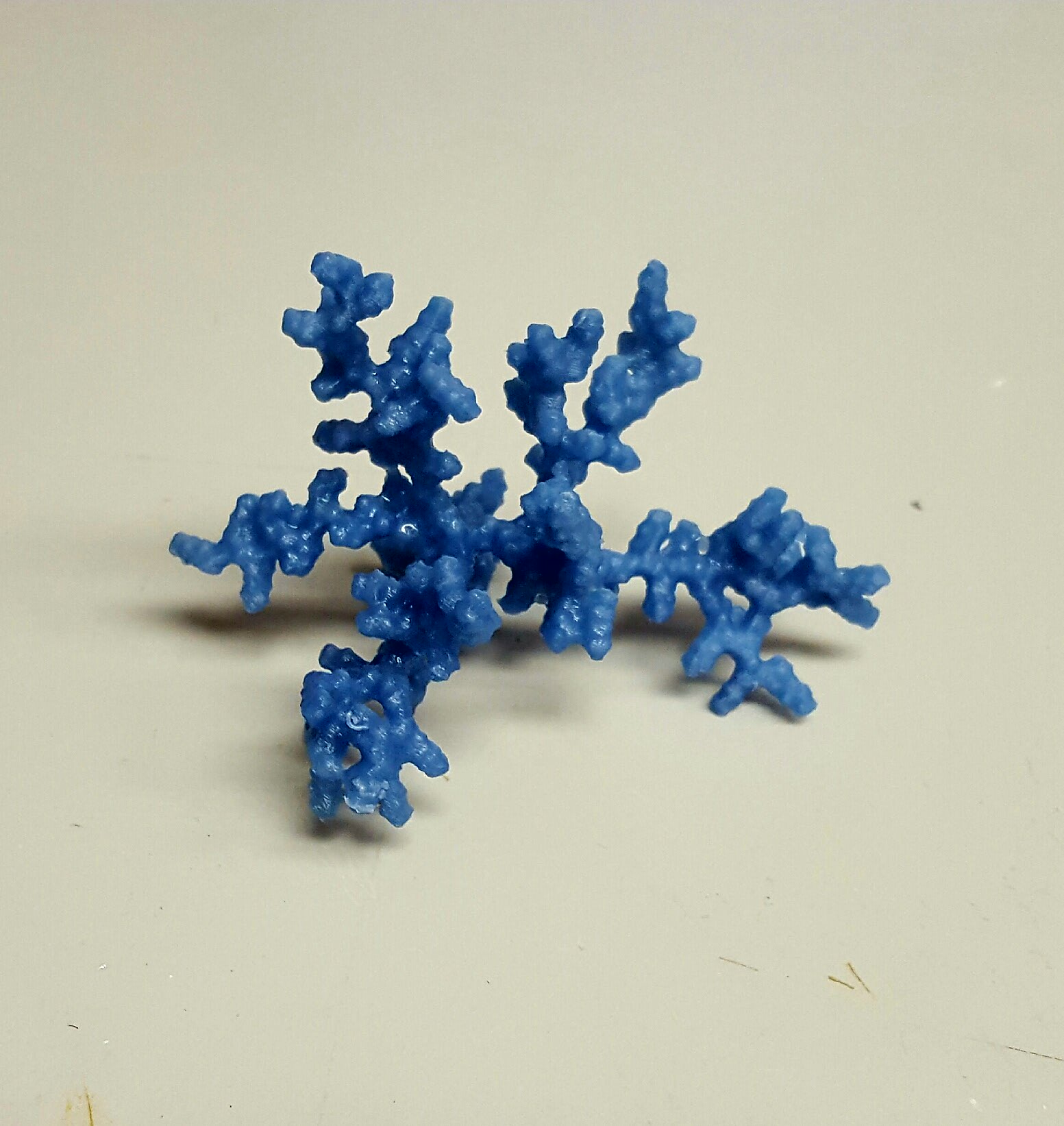

For the post-processing part, I simply sonicated the model for a few hours at 40°C in water. No manual intervention was required. When I took the model out of the sonicator, it looked absolutely perfect. I could not notice any support residue:

I also repeated the same procedure for a fourth generation DGL (DGL G4, PDB here, on the right of the picture):

I think the combination dual extruder/soluble material allows FDM printers to fill the gap between them and more “industrial” printers, for a much lower price.